Controlled Stub Welding System

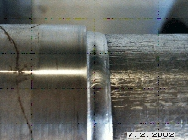

The system can stub various material using the Hot Wire TIG welding process. There should be a minimum of .250" thickness for the backing ring. However, there are no limitations on the tube length or type of material.

The welding process has a controller, which controls the arc length, welding current, wire feed speed and rotary travel.

The welding torch is mounted on an AVC Box, which enables the system to maintain a precise voltage as well as arc length. This helps control the dilution of filler material into the base material enabling the system to use less heat on the base material and more heat is supplied into the filler material.

The hot wire attachment allows for the stub welding of stainless steel with parameters of 1.01u magnetic permeability. The attachment also allows the operator to adjust the heat input without changing the amperage during the process.

All of these features allow the system to provide a more accurate control of the welding parameters, thus allowing for a semi-automated multi-pass weld.